The total chain is only as strong as its weakest link. This statement obviously applies to everything. All coating systems can be tested among the most extreme conditions, but why do some systems not meet these conditions. For various applications, a particular coating system is recommended. For example, a coating system which is placed in an outdoor installation, on the coast, will be subject to different demands than a coating system which is used in a dry environment.

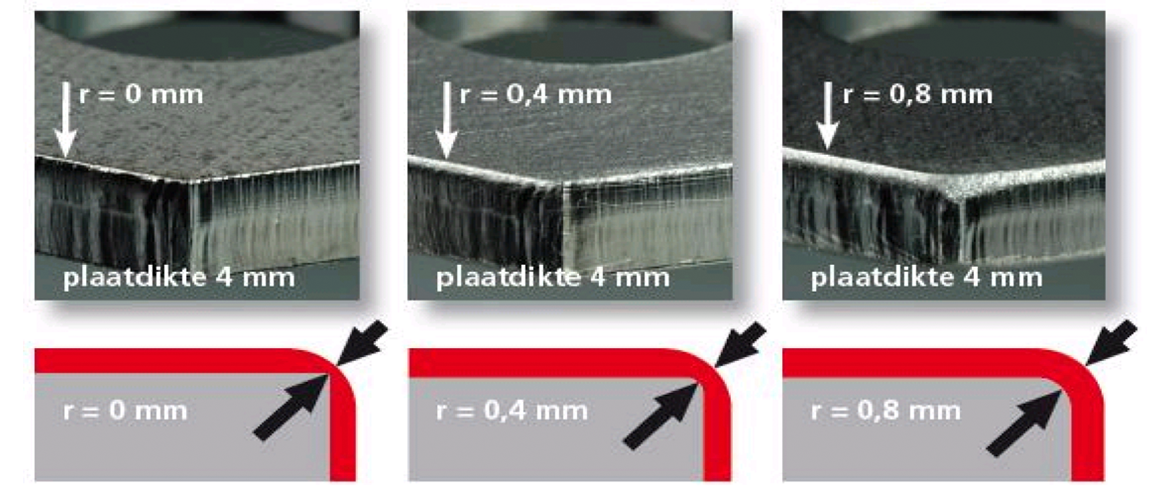

One-, two- or multi-layer systems are therefore always applicable. The obtained layer thickness and the applied coating are therefore always the protective factors of the underlying metal. With powder coating, it is no problem at all to inject 80 microns. For example, one operation on a flat surface. On these surfaces than normally occurs no corrosion. The biggest problems always arise from the sharp edges and corners. When these sharp edges and corners are not rounded enough or deburred, this will always be the weakest link of the entire coating system.

An sharp edge or corner is subject to insufficient film thickness, and thus this is insufficient protection. This is particularly important for applications such as architectural perforated panels, these panels will have to meet certain conditions. All edges and corners should be rounded with a radius of at least 0.5 mm. The perforation holes should be as large as possible, most preferably not smaller than 10 mm. When the starting material meets these requirements, it will always have a two-layer coating system in order to achieve sufficient edge coverage and therefore protection.

For deburring and edge rounding solutions visit the link below.

Click here to view the range of Q-Fin solutions.

Q-Fin is a company that has perfect finishing and deburring machines. This Dutch manufacturer develops and builds machines for deburring, grinding and finishing of metal parts. Suitable for stainless steel, aluminium, steel and various plastics their is a solution for every requirement.