Seaming without Limits!

The RAS 22.07 SpeedySeamer with seven rollforming stations is a multi-functional and cost-efficient machine for varying uses in the HVAC ducting industry. The top of the line RAS 22.09 SpeedySeamer is a 9-station high quality system. Both machines are designed for sheet thicknesses up to 1.5 mm mild steel. The profiles can be as high as 20 mm and the machines reach a speed of 16 m/min.

The machines can have two sets of rolls set up at a time. This allows to have a set of Pittsburgh Rolls on one side and a set of Standing Seam Rolls on the other side. The same could be done with a set of Snap Lock Rolls on one side and Cam Standing Rolls on the other. The rolls are made from the highest quality case-hardened special steel. For additional safety the sheet support tables can be adjusted to the different run heights of the right and left roller set.

Roller shafts, housed in axial and radial roller bearings, provide high-quality profiles. A wide gear box supports the roller shafts in the best possible way. The high-quality gear motor ensures smooth and quite running. It brings the drive power directly to rolls without transfer gears or belt drives in between.

The wear resistant and hardened entrance guiding system is not in contact with the usually plasma-cut material edges. Graved run-in sheet support tables thus belong to the past. Blanks stiffened with Z-seams can be processed easily, as the material guiding system uses downhold pins in the squaring arm. An optional leveling unit allows to straighten seamed blanks or round them for radius cheeks.

Ask for the RAS roller sets.

RAS SpeedySeamer with SealJet for Snaplock Seam

A vital factor in the air duct industry is the quality of the seam, which impacts the energy efficiency of the air duct.

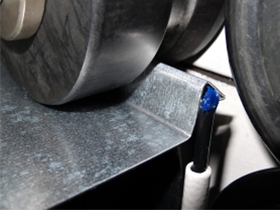

RAS has adapted the SealJet injection unit for sealing the Snaplock seam produced on the SpeedySeamer RAS 22.09.

SealJet for Snaplock Seam

• Fast and easy, efficient and clean seam sealing while the Snaplock runs through the SpeedySeamer.

• SealJet injects a precision amount of the Mez-Bluemastic-Gel sealant.

• Except for 5.5-6 bar (73-80 PSI) air pressure, the SealJet requires no additional power source.

• A sensor starts the injection process when the seam passes a nozzle and stops immediately after the blank has passed through.

• Mez-Bluemastic-Gel is temperature resistant from minus 30°C (minus 22°F) up to 160°C (320°F) and offers protection

against corrosion (corrosion grade 0).

• The sealant meets the strictest health requirements of VDI 6022 and EN 15780.

• Mez-Bluemastic-Gel is available in 25 kg (55 lbs) packaging.

• Each bin contains adequate sealant for sealing about 4,500 meters (14,750 ft) of ductwork.

• Ideal for snap lock seams starting at 0.7 mm (22 ga) material thickness.

• Best results on straight ducts. Reaches tightness class C or D.

• The SealJet injection unit can be retrofitted to existing machines!

| Ras SpeedySeamer 22.09 | Ras Speedyseamer 22.07 | |

|---|---|---|

| Rollforming stations | 9 | 7 |

| Material thickness max. | 1.5 mm | 1.5mm |

| Speed approx | 16 m/min | 16 m/min |